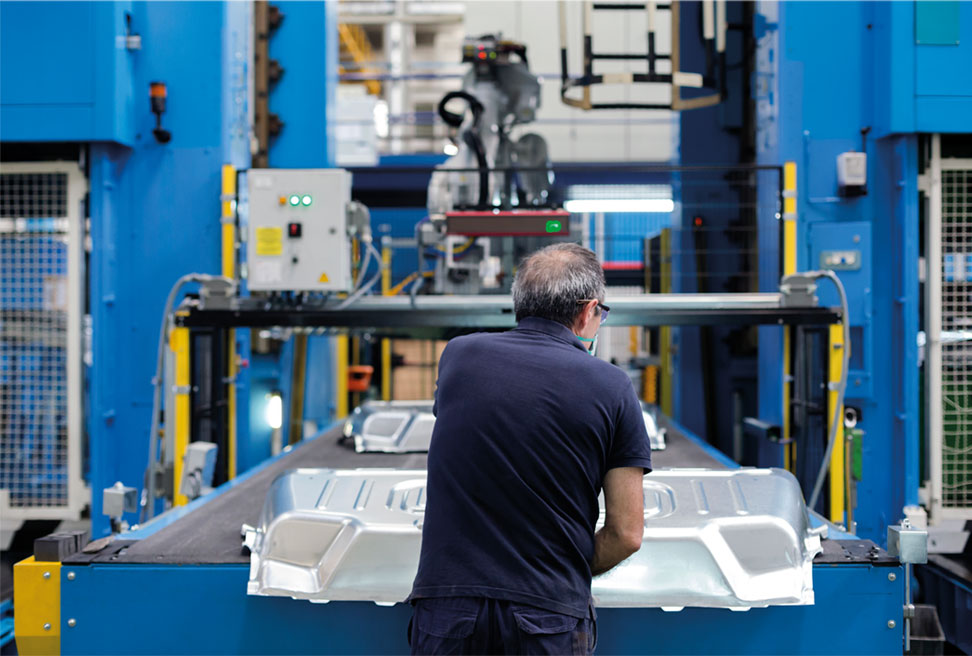

80 years of experience in the automotive sector

The automotive is closely linked to ORAN’s history.

Our lengthy trajectory has allowed us to developus remarkable know-how and a good share of the experience we apply in our projects and those of other sectors.

80 years in which we have not only applied our principle of continuous improvement, but also we’ve developped one of our greatest strengths: flexibility.

Thanks to it, we’ve been able to adapt to the constant evolution of the sector, as well as to adapt to the needs of our clients through all this years.

Flexiblity allow us to adapt to give our clients the maximum value added

Production of big batches

Small batches for high-end vehicles

After-market production

Adaptation from transfer to tandem process in a competitive way

Maintenace, repair and overhaul of toolings

Our quest to add value to our clients has led us to offer a highly flexible service. This allow us to focus the projects according to the characteristics and specific opportunities of each case.

We adapt to your needs, whether you want us to take care of the whole production process or just one stage of it.

Technical office, engineering and project management

CAM programming (Tebis with CATIA module)

Milling

_Gantry milling machines with tables up to 6.000 x 2.000 mm

_High speed copy machines with tables up to 4.500 x 2.500 mm

_5 axis milling (diameter of table 570mm – 16.000 rpm)

Assembly and adjustment

Try-out press

4 robotized tandem press lines

_Possibility of integration of 3D laser cutting in-line

_Presses of up to 1.200 tones

_Tables up to 3.000 x 2.000 mm

Metrology

_Tactile CMM and laser scanning

_Independent measuring room

_Working measuring area up to 5.000 x 1.800 x 2.100 mm (x,y,z)

Welding of assemblies in robotized cells

Welding in flexible posts

Robotized mastic application

Hemming both with tooling in a press and in a robotized roll-hemming cell

Superficial treatment and painting

_Degreasing

_Washing

_Phospate conversion coating

_Painting

A strategic partner for leading suppliers

Committed to quality and demanding with our own work, we are always in the search of finding improvement in our services. Our highly trained team, backed with the analysis of the data gathered from our processes, help us deliver our best. A service endorsed by the IATF 16949 certification.

Our quality department, leaning on a resourceful metrology center, guarantees the repetition

of our fabrication, as well as the capability of our productive processes.